Modern power train components are being designed with greater capacity & performance characteristics, which often corresponds to an increase in component size and weight. Replacing these components presents a unique challenge to the Heavy Lift Contractor due to increasingly restrictive headroom constraints, especially when using existing Plant overhead craneage.

These installations are further complicated because low-headroom rigging arrangements are typically susceptible to instability failures wherein the narrow or shallow upper rigging is unable to maintain a level lift via unequal tension forces in each rigging leg.

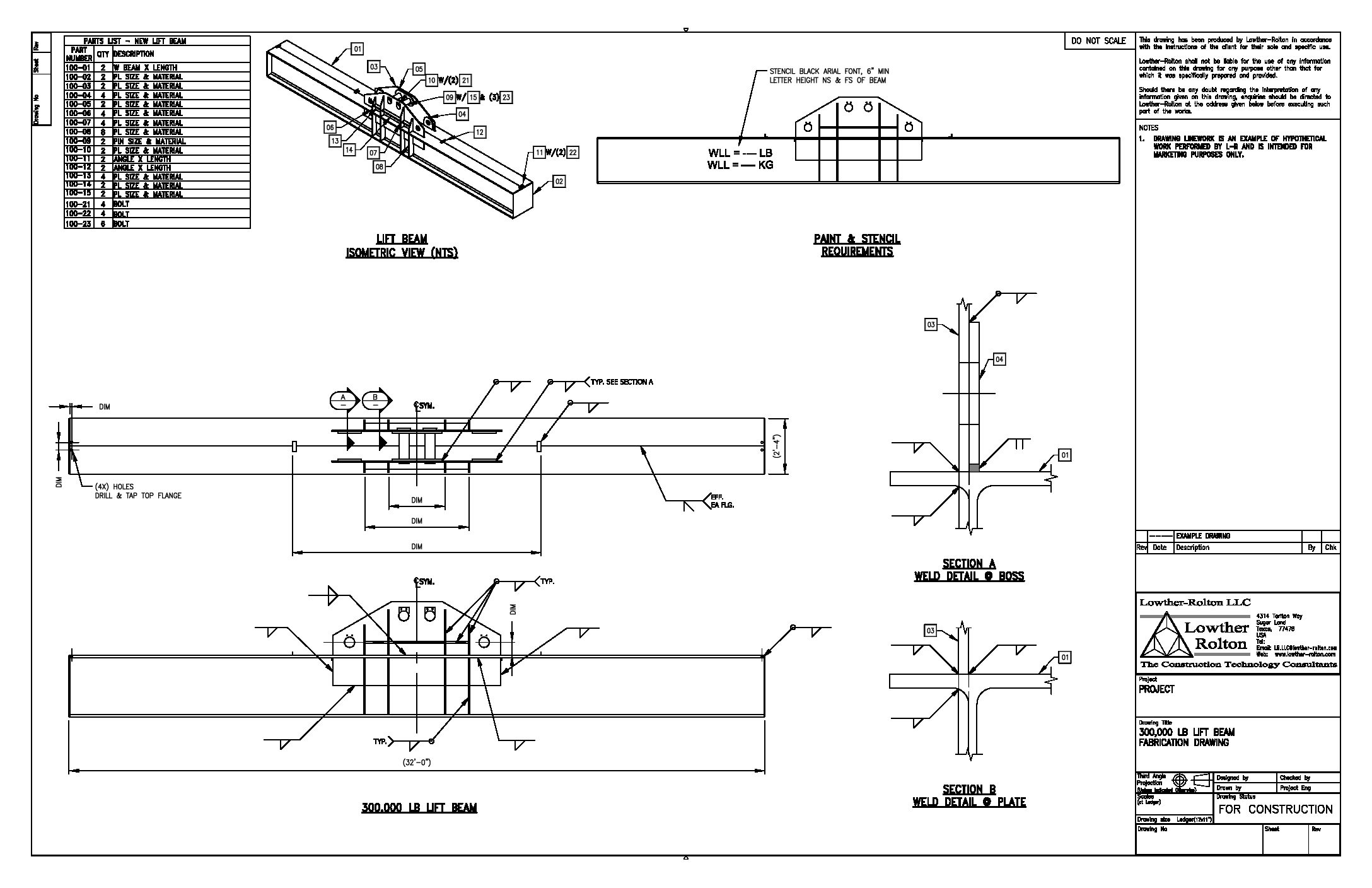

Lowther-Rolton was hired to design/upgrade an existing lift beam such that larger, heavier components could be safely installed into existing power plants with minimal available headroom. The result is a lift beam with spare weight capacity in anticipation of improved (and larger/heavier) power train components that is also resistant to the type of instability that is commonly a risk in these types of lifts.

Lowther-Rolton ultimately provided a highly versatile connection design with ample upper rigging stability. The connection is acceptable for direct pinning to various duplex crane hook sizes, as well as using standard rigging arrangements with shallow rigging angles. The connection design required a blend of operational familiarity with these types of lifts and specialized structural engineering expertise to ensure a utilitarian, economical, and safe design.