Lowther-Rolton were appointed by our Client to undertake a feasibility study to determine the craneage and transportation requirements for the delivery and installation of process Columns, PAUs and other process equipment items, into the live plant, as part of their Project. Engaging Lowther-Rolton at an early stage of the Project enabled the Client to consider various transport and installation options and their potential effect on other work areas of the Project. The study prepared by L-R independently of specific equipment operated by any Contractor allowed various options to be considered by the Project team in the early stages and maintained flexibility for the Project.

The PAUs, Columns and process equipment, being manufactured remotely in Europe, arrived by barge at the public dock facility before being transported 3 miles on public roads and installed at the Project location into the live plant, surrounded by 3 Flare lines and a Heater bank.

Lowther-Rolton undertook a route survey of suitable routes from the dock to the Chemical Plant, which included liaising with local authorities regarding the traversing over the historic stone arch bridge, with limiting axle loads and width restrictions. This enabled the preferred route to be established prior to the T&HL contract being tendered and allowed structural checks of the stone arch bridge to be technically assessed in advance of the T&HL contract being awarded.

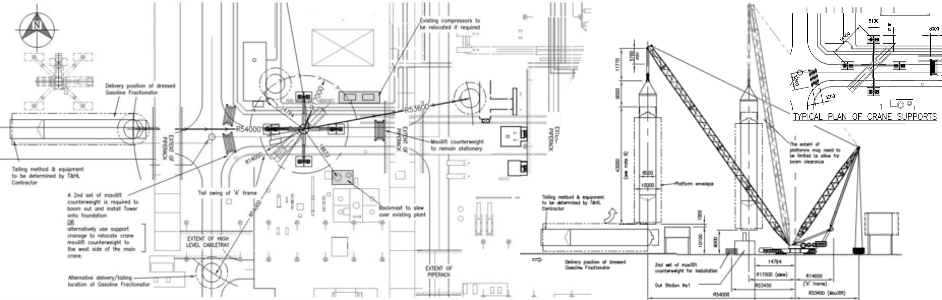

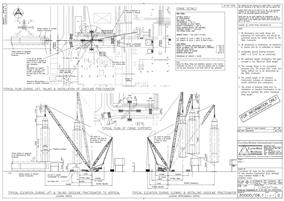

Lowther-Rolton completed an on-site survey as part of the feasibility process to determine various installation options independent of any specific installation equipment available. Our concept drawings and supporting documentation formed part of the tender enquiry issued by the Client to T&HL Contractors. Supplying this information to the T&HL Contractors provided a base from which their tender could be considered, improving the quality and definition of each tender received.

L-R provided the Client with valuable design information regarding the ground preparation and crane foundation requirements to suit a number of alternative cranes prior to award of the T&HL contract, allowing piled crane foundations to be constructed suitable for the different crane outrigger/crawler track footprint at a time to suit the overall schedule of the Project.

Following receipt of the T&HL tenders, Lowther-Rolton completed a technical assessment of the proposals received and were able to advise our Client of any areas that further clarification/information should be provided by each T&HL Contractor, ensuring that each tender received was priced on a ‘like for like’ basis.

The engineered proposals issued by the successful T&HL Contractor were subject to our independent 3rd party Technical Audit process, ensuring all aspects of the transportation and lifting activities were accommodated and that the operational activities could be completed in an efficient and safe manner. Our Technical Audit checks comprised design and operational checks, including site attendance during load-out/load-in, transportation and installation ensuring the agreed procedures were followed. Design checks completed by L-R included lifting/tailing attachments, base ring strength, vessel/module local and global stresses, ground conditions and all other associated engineering aspects.

Lowther-Rolton is the premier independent engineering consultancy for Heavy Lift & Construction Engineering, providing original in-house design and third party verification services.